Nesting software technology has revolutionized the manufacturing industry, providing precision and efficiency to help businesses streamline their production processes. This advanced software technology has enabled manufacturers to optimize material usage, reduce material waste, and increase productivity, resulting in superior results and cost savings. In today’s competitive market, it has become essential for manufacturing companies to adopt efficient layouts in order to stay ahead of the competition. This article will delve into the world of nesting software technology, exploring its capabilities and how it has transformed the manufacturing landscape. We will examine the key features of nesting software, its benefits, and the industries that have benefited from its implementation. Furthermore, we will take a closer look at the various types of nesting software available in the market and how they cater to different manufacturing needs. By the end of this deep dive, you will have a comprehensive understanding of nesting software technology and its powerful impact on the manufacturing industry. So, let us dive in and discover the possibilities of efficient layouts and superior results with nesting software technology.

Streamline production with nesting software

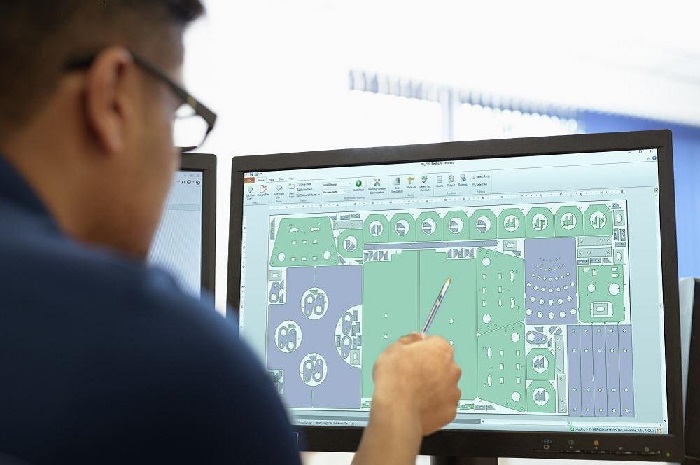

Nesting software has revolutionized the manufacturing industry by offering a powerful solution that streamlines production processes and maximizes material utilization. By intelligently arranging and optimizing the placement of parts on a sheet of material, nesting software eliminates waste and reduces production time. It utilizes advanced algorithms to determine the most efficient layout, taking into account factors such as material size, shape, and quantity, as well as any specific constraints or requirements. With the ability to handle complex nesting tasks quickly and accurately, nesting software provides manufacturers with the opportunity to achieve superior results, improve productivity, and ultimately, enhance their bottom line.

Maximize material usage and minimize waste

In today’s competitive manufacturing landscape, optimizing material usage and minimizing waste have become imperative for businesses seeking to stay ahead. By implementing efficient nesting software technology, manufacturers can take a deep dive into their production processes, uncovering opportunities to maximize material utilization and minimize unnecessary waste. With precise algorithms and advanced optimization techniques, nesting software enables the intelligent arrangement of parts on a sheet of material, ensuring minimal scrap and optimal use of available resources. By eliminating manual guesswork and relying on data-driven decision-making, manufacturers can achieve significant cost savings, increased productivity, and a more sustainable approach to production. With the ability to accurately analyze material requirements, nesting software empowers manufacturers to achieve superior results in terms of material usage efficiency, ultimately contributing to their overall success in a highly competitive marketplace.

Seamlessly integrate with existing software systems

To further enhance the efficiency and productivity of manufacturing processes, it is crucial for nesting software technology to seamlessly integrate with existing software systems. By seamlessly integrating with CAD/CAM software, ERP systems, and other essential tools, nesting software can seamlessly communicate and exchange data, streamlining the entire production workflow. This integration allows for real-time updates, eliminating the need for manual data entry and reducing the risk of errors and discrepancies. With seamless integration, manufacturers can effectively synchronize information across different systems, enabling better collaboration and coordination between various departments. Additionally, the seamless integration of nesting software with existing systems ensures a smooth transition and minimizes disruption during implementation, enabling manufacturers to quickly leverage the benefits of this advanced technology without major disruptions to existing operations.

Boost efficiency and productivity levels

By leveraging the power of nesting software technology, businesses can significantly boost their efficiency and productivity levels. With advanced algorithms and intelligent optimization capabilities, nesting software can analyze and optimize the placement of parts on materials, minimizing waste and maximizing material utilization. This not only reduces material costs but also improves overall production efficiency. Additionally, nesting software provides accurate estimates of material requirements and production times, allowing businesses to plan and schedule their operations more effectively. By streamlining the production process and eliminating inefficiencies, nesting software technology empowers businesses to achieve superior results, increasing output while reducing costs and enhancing customer satisfaction.

Achieve superior results through advanced technology

With the continuous advancements in technology, businesses are now able to achieve superior results like never before. Through the utilization of cutting-edge software and tools, companies can streamline their operations and optimize their processes to maximize efficiency and productivity. Advanced technology enables businesses to automate tasks, reduce human error, and improve overall accuracy in various aspects of their operations. From inventory management to production planning, these advanced technologies provide businesses with real-time data, analytics, and insights to make informed decisions and drive success. As a result, businesses can achieve superior results in terms of cost savings, time management, and customer satisfaction, ultimately gaining a competitive edge in the market. Embracing advanced technology is no longer an option, but a necessity for businesses looking to stay ahead in today’s fast-paced and digitally-driven world.

Conclusion

It is clear that nesting software technology plays a crucial role in optimizing material usage and improving overall efficiency in manufacturing processes. With its ability to create complex and efficient layouts, this technology offers a valuable solution for businesses looking to reduce costs and increase productivity. As technology continues to advance, we can expect to see even more advancements and improvements in nesting software, making it an essential tool for businesses of all sizes.